Offering an impeccable range of Soda Making Machines.

U R SODA MACHINE

Offering an impeccable range of Soda Making Machines.

About Our Company

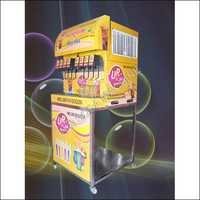

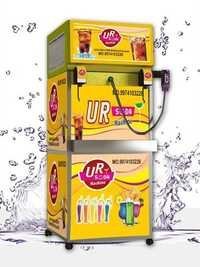

We, U R Soda Machine, founded back in the year 1999, are pleased to introduce ourselves as a dynamic business enterprise. As our name suggests we are a company that deals in a broad assortment of Soda Machines. Some of these include Soda Making Machine, Soda Fountain Machine, Soda Dispenser Machine, Soda Vending Machine and many more. These are available in different specifications from 2 to 8 filters and varied sizes.

We are a quality oriented manufacturer and thus, the raw materials that are implanted by us in the engineering of these products are of A-grade quality. The manufacturing process is carried out as per the guidelines of international quality organizations. These Soda machines are used to pour out different flavors of drinking soda like orange, cola, lemon etc., which is highly refreshing especially in summers. In small food stalls, beverage stalls, restaurants etc., these machines are installed.

What We Offer?

We are engaged in the manufacturing business of a wide range of superior working Soda Machines, which we offer at cost-effective rates. Cite below is our offered gamut:

- Soda Machine

- Soda Making Machine

- Soda Vending Machine

- Soda Fountain Machine

- Soda Dispenser Machine

Our Infrastructure Facility

A state-of-the-art infrastructure facility is owned by us in the industrial location of Bhavnagar, which was specifically constructed by us so that we can have the best of the production facilities. Our infra is outfitted with all requisite raw materials, technical amenities, safety management solutions that are required by our engineers, packaging experts, quality controllers and other production staff during the manufacturing of the products. A hassle free operation conducted by our workers from the very beginning till end.

Quality Assurance Strategy

The variety of Soda Machines that are manufactured at our end are passed through a stringent quality check at every stage of production and before being dispatched in the market so that our customers get a flawless working machines. Our quality analysts adhere to the set quality standards and norms during the QC process and test attributes like mechanical/ technical features like efficiency, power consumption, functional life and many other. On the other hand, they also examine the physical attributes like the design and structure of the machines.

-

6+2 Soda Fountain Machine -

5+1 Soda Fountain machine -

8+2 Soda Fountain Machine -

8+1 Soda Fountain Machine -

36+6 soda Fountain machine -

2+1 Soda machine -

8+2 Soda Machine -

4+1 Soda Machine -

11+1 Soda machine -

7+1 Soda machine -

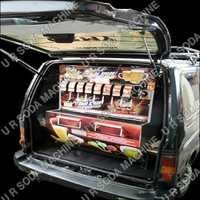

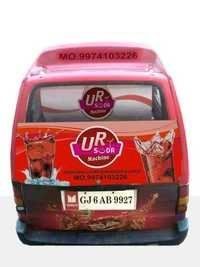

6+2 Mobile Van Soda Machine -

Maruti Van Soda Machine -

6+2 Soda machine Mobile Van machine -

Mobile van soda fountain machine -

Mobile Van Soda Machine -

Soda Shop Machine Gujarat -

Soda Shop machine -

Soda Shop Machine -

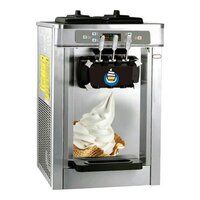

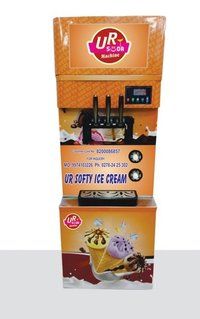

Softy making machine -

Ice Cream Softy machine -

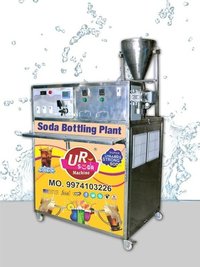

Soda Bottling Machine -

Soda Bottling machine -

sugarcane juicer -

Sugarcane Juice machine -

8+2 Soda Vending Machine -

6+2 Soda Vending Machine -

8+1 Soda Vending Machine -

8+2 Soda Vending Machine -

Flo jet co2 syrup pump -

Imported jetco regulator -

Brass Soda Fountain Machine -

co2 Soda Machine Connecter -

Soda Machine Flare Nut